Solutions

Local Manufacturing – Global Capabilities

For over 35 years, OSI Electronics has provided Manufacturing Solutions of the highest quality, reliability, and customer support. We specialise in customised Manufacturing Solutions with the portfolio of services, capabilities, and factory locations needed to provide our customers with a competitive advantage in the global marketplace.

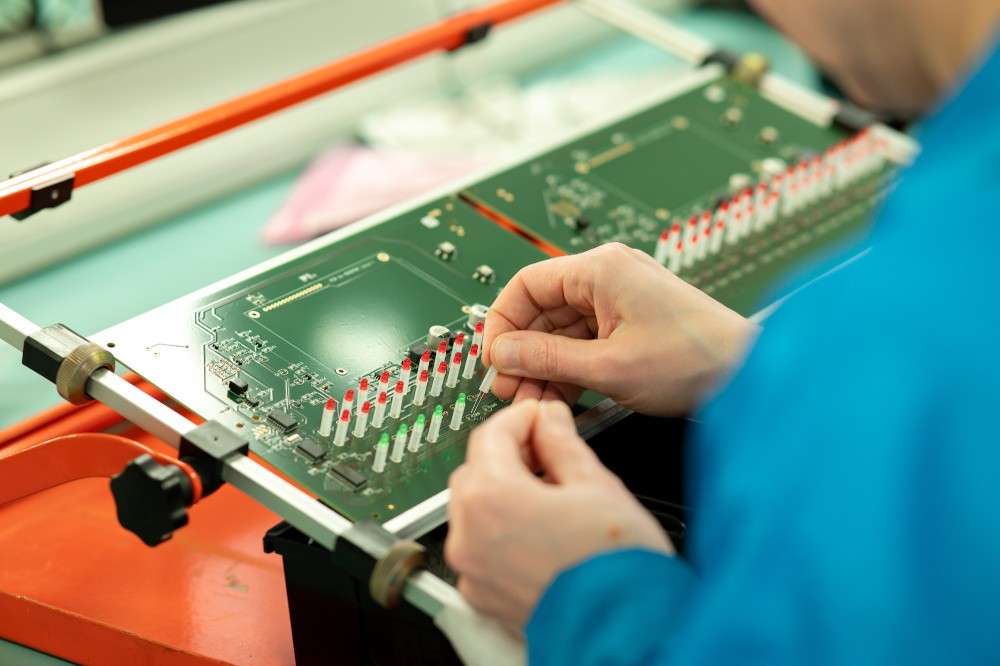

Design & Engineering

Our engineers can work as part of your design team or take on complete product designs for you. Through close integration with our manufacturing team we ensure that the design transitions quickly from design to prototype and into production.

Fast Track Prototyping/NPI

Our fast prototype service has become a key element in customers’ new product introduction (NPI) programmes.

PCBA

We manufacture complete printed circuit board assemblies – surface mount and through-hole – tailored to the design, specification and volume of your project.

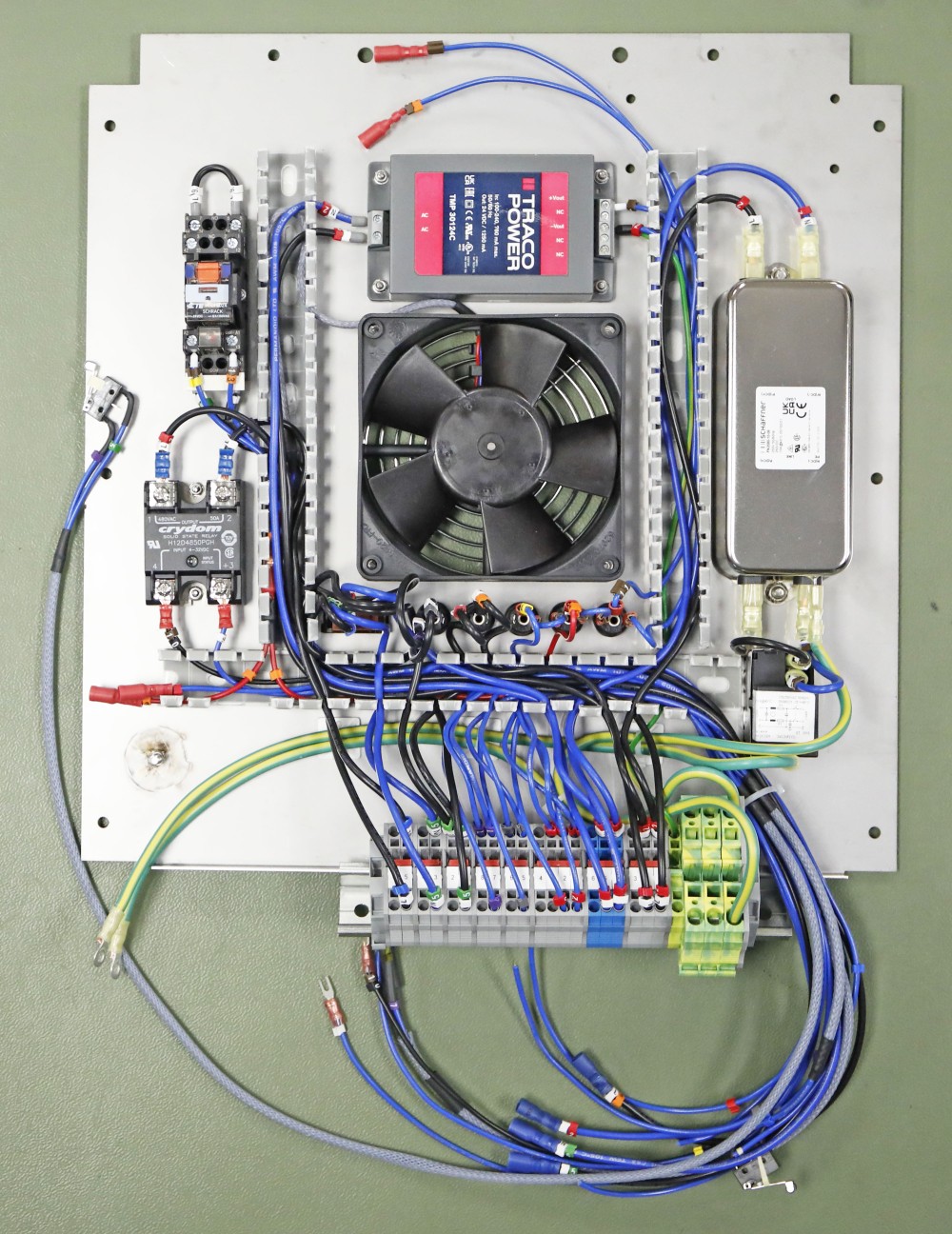

Box Build

From your drawings, we can manufacture complete complex (and not-so-complex) electronic products in volumes to suit your requirements. We will take your electronics project right through the manufacturing process, including PCB Assembly and deliver finished boxed products anywhere in the world ready to sell or install without the need for further testing

Sub Assembly

We provide sub-systems to major OEMs – from your drawings, we can manufacture complete complex (and not-so-complex) sub-systems in volumes to suit your requirements.

Global Procurement

OSI Electronics UK is part of the OSI group – which has a $120m+ budget for purchasing components: electronic, electrical and mechanical; we work in conjunction with our teams globally to leverage both our purchasing power and availability of parts worldwide. Our UK team of purchasing specialist have a wealth of knowledge in the electronics industry and are always striving to attain the best possible service for our customers – so it’s not surprising they’re always able to find the right components for each project: it is part of the added value of using OSI Electronics.

Serving Your Market

OSI Electronics provides turnkey design and manufacturing services, flex circuit design and fabrication, LCD display, and Optoelectronic solutions across several high-tech markets. Our facilities are certified to meet the unique process, quality, and regulatory requirements of our customers and their markets. We support the ever-changing requirements of each of these markets so that we can be successful together.

Medical & Life Sciences

Communications

Commercial and IoT

Automotive

Aerospace & Defense

Security

News & Events

Welcome to the family!

2024-01-19

We are delighted to announce our new factory in Tecate, Baja California, Mexico, and extend a warm …

Read More