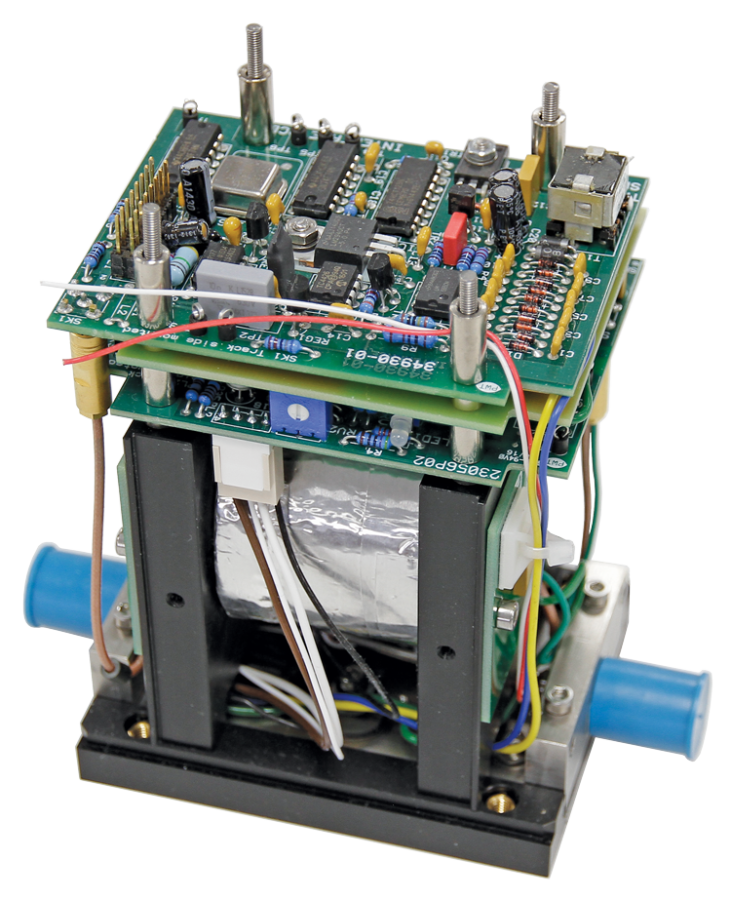

High Level Assembly

We have vast experience in sub-assemblies and integrating electronics into a full system build including complex high-level assemblies such as medical equipment, semiconductor manufacturing systems, digital printers, data logging, high end audio and more.

Vertical integration and end-to-end solutions simplify the supply chain and speed up time to market for our customers.

Our global facilities are vertically integrated to provide seamless higher-level assemblies and system builds offering our customers .

UK, North America, Mexico, South East Asia : FDA-registered for medical products – AS9100 for Mil/Aero projects: Prototype, NPI, small to medium volume, high volume – One company many solutions