Printed Circuit Board Assembly

We manufacture complete printed circuit board assemblies – surface mount and through-hole – tailored to the design, specification and volume of your project.

We manufacture complete printed circuit board assemblies – surface mount and through-hole – tailored to the design, specification and volume of your project.

We manufacture complete printed circuit board assemblies – surface mount and through-hole – tailored to the design, specification and volume of your project.

Our facilities include:

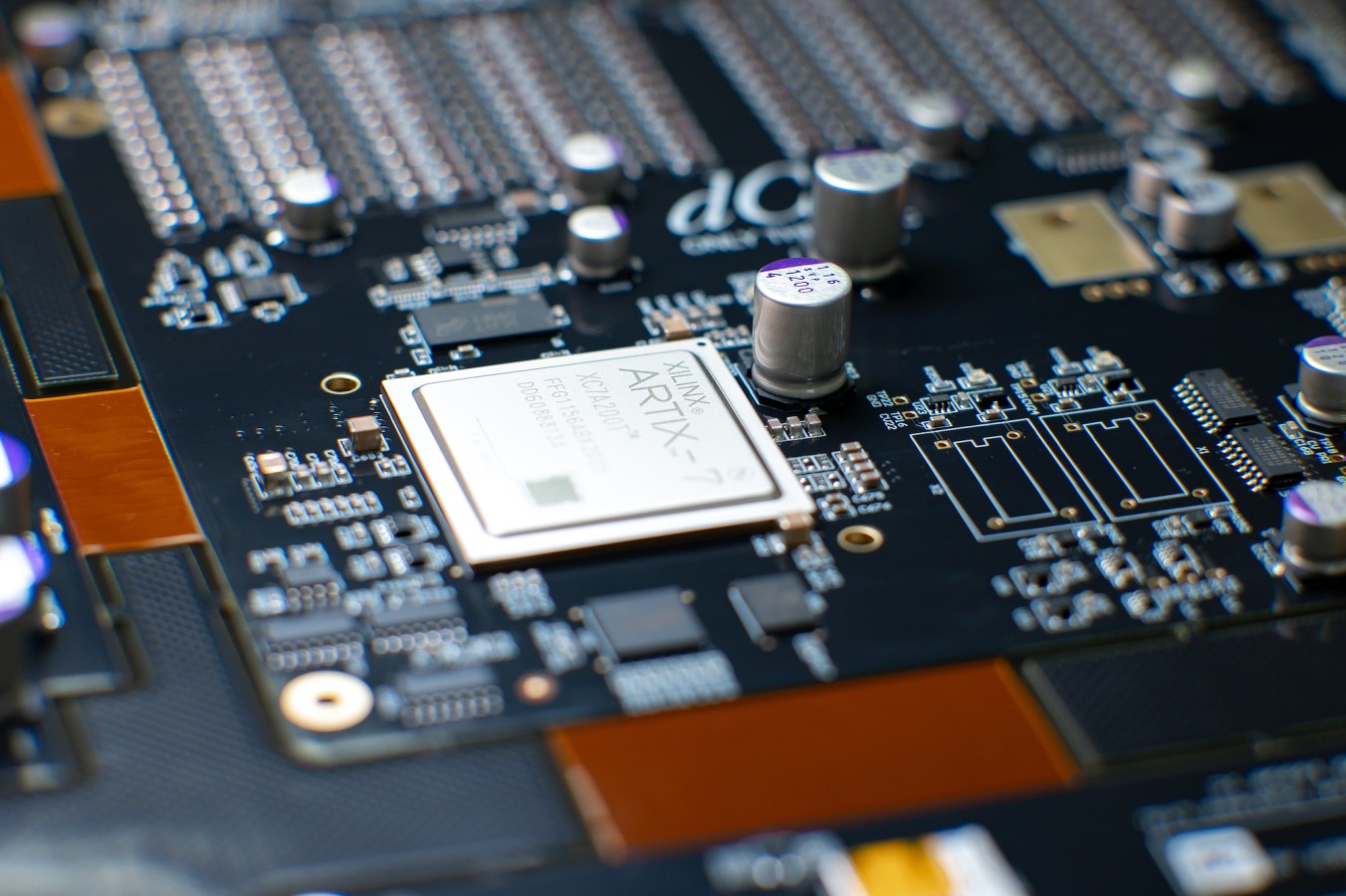

Our PCB capabilities include flip chips, package-on-package (PoP), plugged, blind and buried vias, flexible circuits, thermal substrates and x-ray inspection.

As it leaves the production line, each PCB is automatically inspected with state-of-the-art AOI equipment (with manual inspection if required) to ensure the board is 100% defect-free before other assembly work.

In addition to our UK site, we have manufacturing plants in Indonesia (where there are 12 high-performance SMT lines), Malaysia, Mexico and North America allowing us to integrate your EMS seamlessly around the world to suit your market requirements.

Our surface mount capability is at the heart of our business, with five high speed Europlacer units over three SMT lines to deliver the highest quality product with the greatest flexibility.

We can place components as small as 01005 passives, 0.3 mm pitch and BGAs with a pitch of 0.4 mm.

Our latest investment has brought in a new Europlacer screen printer, which can handle boards up to 610 x 515 mm, and a 3D solder paste inspection (SPI) unit – read about the benefits they bring.

Upon completion of the SMT assembly stage, each board is carefully checked using our Mirtec and ALeader AOI systems in combination with a Dage XiDAT x-ray real time system to verify the soldering of BGAs, LGAs, QFNs and PoP packages meet IPC-A-610 up to Class 3 standards.

In addition to our on-line equipment, we have also made a considerable investment in our off-line facilities including the latest interchangeable carts for rapid change over and improved lead-times.

When procuring materials on your behalf – electronic, mechanical and fabricated – we’re helping your cash flow; as we also forward order and schedule, the savings are passed on to you through a more competitively priced assembly. We also offer traceability services such as - strategic minerals, country of origin, life cycle monitoring and more.

We’re also happy to use your free issued parts and manage them through our system to reduce your stock holding, material commitment and your time in managing materials.

Moisture sensitive devices are stored in accordance with manufacturer recommendations and baked and vacuum sealed or stored in one of our dry stores to maintain shelf life.

See our global procurement page for more information.

But before we start buying components, we like to work with you on design for manufacturing (DfM) your product to minimise costs, maximise production efficiencies and plan the best test procedures.

If you need help with PCB design, we work closely with our sister company who specialise in all types of circuit board technology.

That way your product is optimised for efficient assembly, testing and shipping, making everybody’s life easier – and almost always resulting in a lower price.

Naturally, with high levels of manufacturing expertise, we have very skilled teams of well-trained, experienced and helpful SMT engineering staff who understand the demands of placement accuracy and inspection.

We have accreditations for quality management (ISO 9001: 2015), medical devices (ISO 13485: 2016) and environmental management (ISO 14001: 2015); all are certified ahead of expiry.

Our PCB manufacturing process is certified IPC-A-610 Class 3, Acceptability of Electronic Assemblies. Class 3 is the highest class. Click to our special news item on this.

We are also an approved sub-contractor under the ATEX Directive and a certified sub-contractor for UL Approved Products.

And overseas, our facilities in Indonesia, Malaysia and the North America have AS 9100 certification for aerospace, defence and military work and ISO/TS 16949 for automotive applications.

PCB assembly is only one part of any project. We have agile manufacturing facilities, giving you a resource to develop, make and deliver complete products to anywhere in the world.

Contact us today on 01480 222 480 / info@osi-electronics.uk.